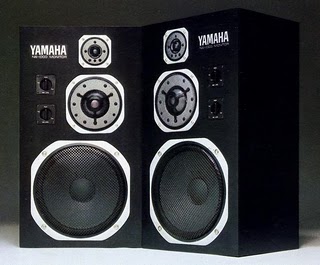

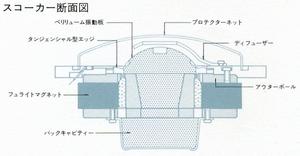

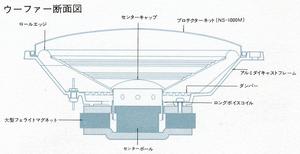

YAMAHA NS-1000/NS-1000M 12in Woofer

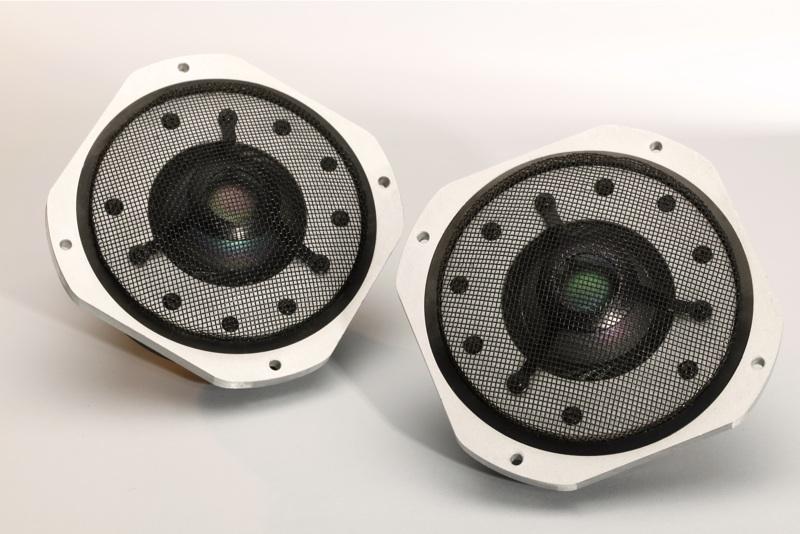

JA-3058A

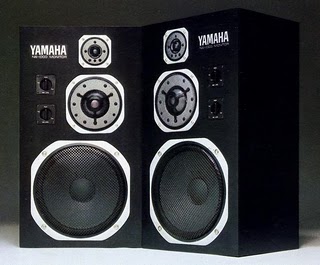

YAMAHA NS-1000/NS-1000M

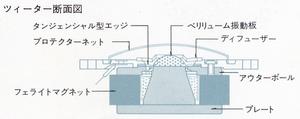

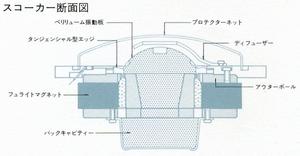

Beryllium Dome Midrange JA-0801

YAMAHA NS-1000/NS-1000M

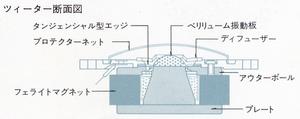

Beryllium Tweeter JA-0513

YAMAHA

NS-1000M

1974 sale ¥108,000/each ~750usd/each (1 unit, around 1978) ¥119,000 (1 unit, around

1993)

System:3 ways 3 speakers

airtightness system bookshelf type

Use unit:It is low the

for limits: 30cm cone type (JA-3058A)For middle limits: 8.8cm dome type

(JA-0801)For high pass: 3.0cm dome type (JA-0513)

Playback frequency

zone:40Hz - 20kHz

Crossover frequency:500Hz, 6kHz

and 3 way-12dB/oct

Lowest resonance

frequency:40Hz

Impedance:8 Ω

Output

overpressure value:90dB/W/m

Rated input (JIS

continuation):50W

Maximum permissible

input:100W

Level controller:Medium treble and

continual variable type

External size:Width 375× height 675×

depth 326mm (NS1000M)

Weight:31kg (NS1000M)

Mid-range level control : ±3dB continuous

Treble level control : ±3dB continuous

Tweeter : 3cm (JA-0513)

Mid-range : 8,8cm (JA-0801)

Woofer : 30cm (JA-3058A, NS1000M)

Finish : black semi-gloss (NS1000M)

Explanation

Throwing the Yamaha individual technology of

the origin and the beryllium diaphragm etc. of the basic idea that it probably

will make those which are regularly used to be long as reference the speaker

system which was developed.It was sold 23 years to 1997 over the long period of

time when you say from 1974, it was used with the Swedish government-managed

broadcast and the Finnish government-managed broadcast as the monitor

speaker.

The beryllium diaphragm is adopted for the

diaphragm of medium high pass.This diaphragm applies electron beam vacuum vapor

deposition method and the special alloy technology which are used for LSI

manufacturing technology, being something which succeeds in development with

individual technical power, in order to produce in the high vacuum, chemical

compound is less than those which it finishes with the rolling plate actualizes

high purity.In addition, to one time atomic condition or a plasma condition

after in order to evaporate, with contraction formation difficult deep dome

shape and those etc. which have the tangential edge, have become production

possible.Furthermore, harmfulness in the atmosphere it has succeeded in also

protecting from the components by administering special coating to the beryllium

material which is easy to corrode with thickness of approximately 5 microns.Low

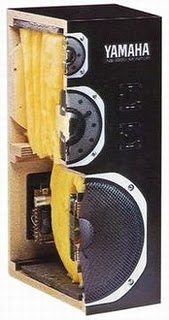

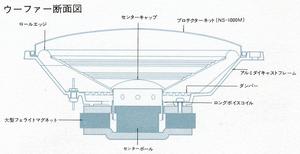

JA-3058A which is the 30cm cone type woofer is loaded in the limits.The

corrugation being attached cone paper which was developed from experience of the

accumulation of long time material research is adopted to the diaphragm.

In addition double coating is done the cloth

which can use the visco-elastic polymers of the thermosetting metaplasia resin

and the resonance holding down to the edge, raises the linearity for the input

signal.We adopt the ferrite magnet 156 φ to the magnetic circuit, voice coil has

become edge wise volume of the copper ribbon line.JA-0801 which is 8.8cm dome

type スコーカー is loaded in the middle limits.The beryllium diaphragm of the

diaphragm diameter 68mm by Yamaha individual manufacturing method is adopted. In

addition in the edge the tangential edge of the double coating which

impregnation it could point the visco-elastic polymers and the thermosetting

metaplasia resin which are the research result at the time of the software dome

opening departure of NS-690 and the like is adopted, sufficient form retention

central retention ability is obtained without impairing the merit of

beryllium.

In addition, voice coil adopts the large

aperture 66 φ, assures the increase of efficiency by the fact that it makes

copper ribbon line edge wise volume.As for this vibrating system in order, for

pneumatics of back of each part such as the beryllium diaphragm voice coil edge

to become identical, the design which is considered is done. Diaphragm back

leads to the center pole scooping out back cavity, voice coil back boring the

air hole through the sabot of the magnetic circuit, has passed to the back

cavity. In addition back of the edge furthermore boring the air hole through

also the outer pole, via the air hole of the voice coil bobbin, has let escape

the air of the edge.The magnetic circuit has adopted the large-sized magnet 156

φ, obtaining flux density 16,000gauss, it has improved transient quality.In

order increase of rigidity of the diaphragm and to assure the improvement of

directivity, the dome type whose radius of curvature is small is adopted. You

hold down the valley by the interference which because of this to quality on the

axis outside zone happens, by adopting the diffuser, extend quality on the axis

to possible limit wide area, to have improved being connected near crossover

frequency of the eater.To 3.0cm dome type JA-0513 which is the eater is loaded

in high pass.

We adopt the 23mm lightweight diaphragm which

is called below weight 0.03g which utilizes the characteristic of the beryllium

material to the diaphragm, we adopt the tangential edge of the cloth make which

the visco-elastic polymers and the thermosetting metaplasia resin double coating

is done, hold down unnecessary resonance.Voice coil diameter is adopted, the

aluminum wire edge wise volume of 23mm and beryllium diaphragm direct connection

is finished lightweight type even altogether vibration.In addition to NS-690

converting, the center pole of the back space of the voice coil which is the

research result of the eater and the like tapered, you hold down the influence

of resonance e.g., in non- fairing, it fills up the urethane for sound

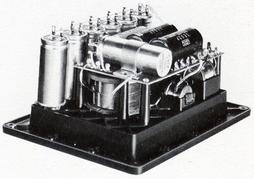

absorbtion.Not only check of electric quality, the basic actual listening

impression is seriously considered in the design of the network section, the

audition is decided over again with cutting and trying.The ホルマール line 1.0 φ is

used to the woofer circuit, and decrease of direct current resistance and

improvement of resistance input characteristics are assured with the adoption of

the large aperture ferrite core entering bobbin.

In addition スコーカー, to large-sized ones whose

resistance input characteristics of the double winding are good are adopted to

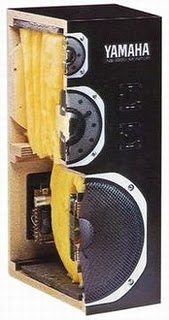

アッテネーター which sets the level of the eater.The enclosure with the bookshelf type

4 surface finish of perfection airtightness, has adopted the design of black

finish.With NS-1000M, front baffle 24mm, the particle board of 20mm is adopted

to rear board 25mm, the side plate, the top board and the sabot. Furthermore

transferring the 24mm thick plywood to the rear board on top of the woofer

installation hole, it makes the firm stiffener, administers appropriate

reinforcement to the various parts.The finish the cross net is not with has

become the black semi- gloss finish.